Cost Effective Food Products Tray Thermoform Vacuum Sealer

Product Description:

Continuous tray sealer is featured with two different types of packages: MAP and vacuum skin pack.It's perfect for the packaging fresh, refrigerated and frozen food, including meat, poultry,seafood,sausages,bacons and prepared fast food.

Advantages

Usually, the capacity is usually 6-8 circles/min.All features controlled by servomotor with high speed and precision.

2,Best Package

Attractive package with top VSP(UniFresh ®) technology. With top Busch vacuum, we can make residual oxygen lower than 1%.

3,Highly customizable

Applied to trays of various shapes and sizes.Anodized aluminum mold with drawer-type design.

Machine

Packages:

Advantage of the Package

- Longer shelf-life

- Easy to carry

- protect the containment

- Easy to open with easy tear design

- totally customizable

Machine details:

Semi-automatic Production

Highly integrated package machine with tray sealing, product filling area, gas flushing and die cutting. Reduce the risk of contacting insanitary source.

Easy Operating

Large size 10" touch screen make the operation easy and safe. The system is simple to learn and easy to use. The machine also have easy mold changing design which makes the mold changing fast and easy.

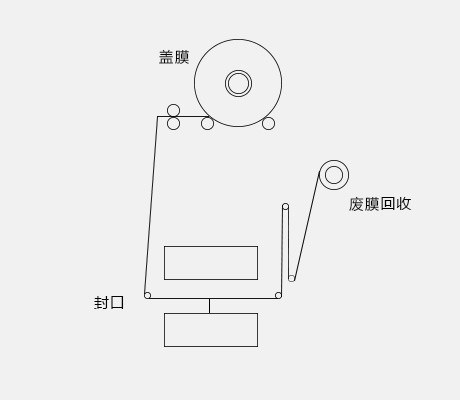

Working Schematic

This machine is based on MAP packaging technology, which vacuum and gas flush the package to make sure the atmosphere inside the package is totally controlled. Automatic cutting makes the package easy to open.

Technical Data

| Working Parameters | |

| Package Type | Sealing/MAP/VSP |

| Speed | 6-8cycles/min |

| Tray Quantity/mold | 3/4/6 |

| Tray Shape | Circular or Rectangle |

| Top Film | |

| Material | Sealable PE\PA Multi-layer Co-extruded Plastic Film |

| Pre-printed Top Film or Transparent Top Film | |

| Roll Diameter | 250mm at most |

| Thickness | ≤200um |

| Components | |

| Vacuum Pump | BUSCH |

| Electrical Components | Scheneider |

| Pneumatic Components | SMC |

| PLC Touch Screen & Servo Motor | DELTA |

| Machine Parameters | |

| Dimensions | 3397mm×1246mm×1801mm |

| Weight | 800kg |

The parameter in this sheet is for reference only, some of the data may be different with different case.

FAQ

Q1:How long does it take to deliver the machine after the order & deposit?

A1:Usually it will take 90 working days to manufacture the machine and make it ready to deliver. At first 30 days the technical drawing will be made. The second 30 days start manufacturing the parts and ready to assemble. In the last 30 days the machine will be assembled and tuned to make sure it is ready to deliver.

Q2:What do you need to make a specific offer for my product?

A2:To make a special offer we will need the dimension(s) of the package(s) you want to use on this machine. We also need the approximate production volume you need per day. If with other special request please also inform us before we make the project.

Q3:Can you offer oversea service?

A3:Yes, if request. But we suggest online problem solving at first. If the problem still shows we can arrange engineer to go to your factory personally to solve the issue.

Utien Pack

Company profile

Utien Pack Co,. Ltd. Known as Utien Pack is a technical enterprise aiming at developing highly automated packaging line. Our current core products covered multiple products over different industries such as food, chemistry, electronic, pharmaceuticals and household chemicals. Utien Pack is founded in 1994 and becoming a well-known brand through 20 years' development. We've achieved 4 national standards drafting and have more than 20 patent technology. Our products are produced under ISO9001:2008 certification requirement. We build high quality packaging machines and make a better life for everyone using the safe packaging technology. We are offering solutions to make a better package and a better future.

Copyright @ Utien Pack Co., Ltd. 2016

255 Shuguang Road, Kebei Industrial Zone, Shaoxing, Zhejiang 312081, China

UTIEN PACK